Mineral resources are essential for industrial development & India is richly endowed with a variety of minerals due to its diverse geological structure. The country has over hundred types of minerals of which around thirty have economic significance. These include coal, iron ore, manganese, bauxite, mica etc. However India has inadequate reserves of some non-ferrous metallic minerals especially copper, lead, zinc, tin & graphite.

Types of Minerals

-

Metallic Minerals

These minerals contain metals in their raw form which can be extracted through various processes for industrial use.

- Ferrous Metals: Minerals that contain iron used primarily in the production of steel & alloys.

- Non-Ferrous Metals: Minerals that do not contain iron & are used in industries such as electronics, aerospace, construction. They include minerals like copper, lead, zinc, gold, silver etc.

-

Non-Metallic Minerals

Non-metallic minerals do not contain metals but are essential in various industries such as construction, chemicals, manufacturing.

- Industrial Minerals: These are used directly in industries without being processed into metal including limestone, mica, graphite.

- Building Materials: Non-metallic minerals used in construction & infrastructure like sand, clay, gypsum, marble.

- Gemstones and Precious Stones: Minerals that are used in jewellery & other decorative arts such as diamonds, rubies, emeralds.

Characteristics of Minerals

Minerals by their nature exhibit range of characteristics that define their properties & behavior. These characteristics are fundamental to identifying, classifying & utilizing them across various industries:

-

Occurrence

- Natural Formation: Minerals are naturally occurring inorganic solids. They are formed by geological processes over time often under high pressure, temperature or through chemical reactions.

- Deposits: Minerals can occur in various geological formations such as rocks, veins or beds. Some may be concentrated in certain areas forming mineral deposits that are economically viable.

-

Chemical Composition

- Fixed Chemical Formula: Every mineral has a specific chemical composition that can be expressed by chemical formula. This defines the elements and their proportions present in the mineral.

- Variety in Composition: Some minerals like feldspar or mica may have a range of compositions due to variations in their elements while others like quartz have a specific composition.

-

Crystal Structure

- Orderly Arrangement: Minerals have a specific internal arrangement of atoms, ions or molecules which results in the formation of crystals. This orderly pattern of atoms defines the mineral’s structure.

- Crystal Systems: The arrangement of atoms in a mineral can result in different crystal systems such as cubic, hexagonal, tetragonal & orthorhombic. Each system has geometric properties.

- Habit and Shape: The shape of a crystal (how it grows in its natural form) can also reflect its internal structure giving us clues about its mineral identity.

-

Hardness

- Resistance to Scratching: Hardness is the mineral’s ability to resist being scratched by other materials. The most common scale to measure this is the Mohs scale which ranges from 1 (talc) to 10 (diamond).

- Use in Industry: Minerals with higher hardness, like diamonds are used for cutting, drilling & grinding while softer minerals are used in applications like cosmetics or construction.

-

Color

- Variation in Color: The color of a mineral is influenced by presence of trace elements, impurities or structural defects. For example, copper gives malachite its green color.

- Not Always Reliable: Color alone is not always a reliable characteristic for identifying minerals because many minerals come in a wide variety of colors due to impurities (e.g., quartz can be clear, pink, purple, etc.).

-

Streak

- Color of Powder: The streak is the color of a mineral in its powdered form, which is observed by rubbing the mineral on streak plate. This characteristic is reliable than color of mineral itself for identification.

- Helps Identify Minerals: Some minerals may appear different in color but leave the same streak aiding in their identification.

-

Luster

- Reflection of Light: Luster refers to the way light interacts with surface of mineral. It can be classified as metallic, glassy, pearly, dull, or greasy.

- Types of Luster:

- Metallic: Minerals like gold or pyrite that shine like metal.

- Non-Metallic: Includes subcategories such as vitreous (glass-like), pearly (like pearl), and resinous (like amber).

-

Cleavage and Fracture

- Cleavage: The tendency of mineral to break along specific planes of weakness in its structure. This results in smooth, flat surfaces. The number and direction of cleavage planes can vary.

- Fracture: Minerals that do not have cleavage tend to break unevenly, producing jagged or irregular surfaces. Common types of fracture include conchoidal (smooth, curved) and uneven fracture.

-

Specific Gravity (Density)

- Weight Relative to Water: Specific gravity is the ratio of the density of a mineral to the density of water. Minerals with a higher specific gravity are denser and heavier for their size.

- Useful in Identification: Specific gravity helps differentiate between minerals that look similar but have different densities (e.g., gold and pyrite).

-

Transparency

- Degree of Light Transmission: Transparency refers to how much light passes through a mineral. It can be classified as transparent, translucent, or opaque.

- Transparent: Light passes through completely (e.g. clear quartz).

- Translucent: Light passes through but is diffused (e.g. frosted glass).

- Opaque: No light passes through (e.g. most metals).

-

Magnetism

- Magnetic Properties: Some minerals like magnetite are magnetic and can attract or repel magnetic objects. These minerals are used in making magnets or magnetic applications.

-

Solubility

- Reaction with Liquids: Some minerals are soluble in water or other solvents like halite (salt). Others are insoluble which is why they persist in nature as solid minerals.

-

Toughness

- Resistance to Breaking: Toughness measures a mineral’s ability to resist breaking, chipping or deforming. It’s different from hardness which is about scratching resistance. A mineral can be hard but brittle like diamond or soft but tough like jade.

-

Fluorescence

- Glow under Ultraviolet Light: Some minerals exhibit fluorescence, meaning they can glow under UV light. This characteristic is used in gemology and mineralogy to identify certain minerals.

-

Taste and Odor

- Rarely Used for Identification: Some minerals like halite (salt) have a distinct taste while others may have an odor when exposed to air. However using taste or odor as identification is rare and not recommended in practice due to safety concerns.

-

Brittleness

- Breakability: Minerals vary in how easily they can break or fracture under stress. Brittle minerals like halite will fracture with little force while others may bend or deform.

-

Transparency and Diaphaneity

- How light interacts: Some minerals are transparent (clear), while others are opaque (no light passes through) or translucent (light partially passes through).

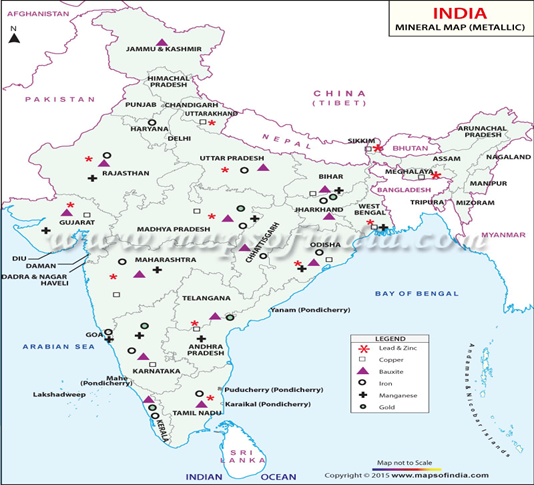

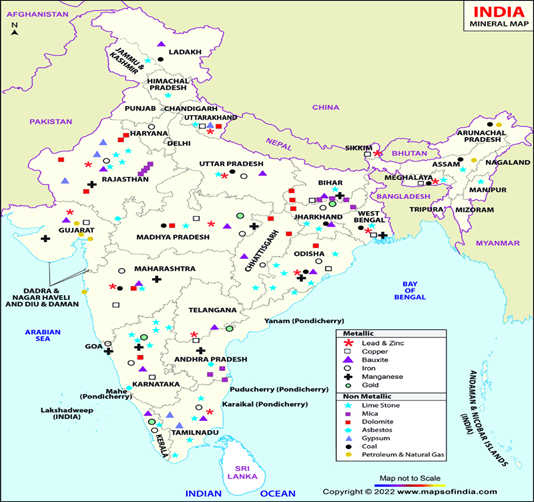

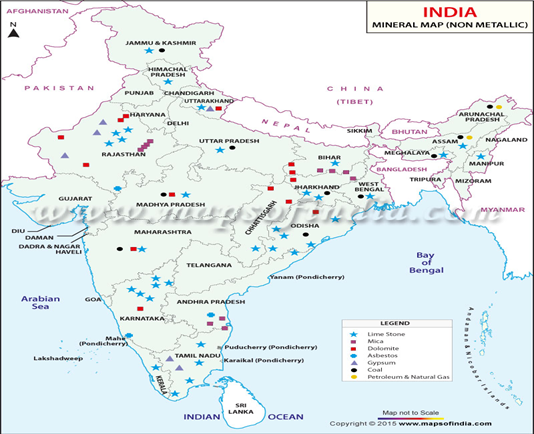

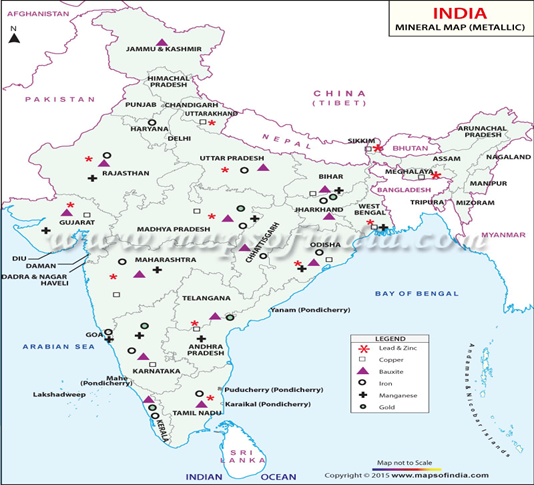

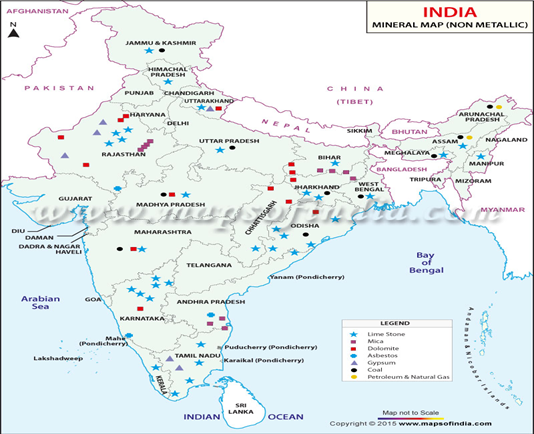

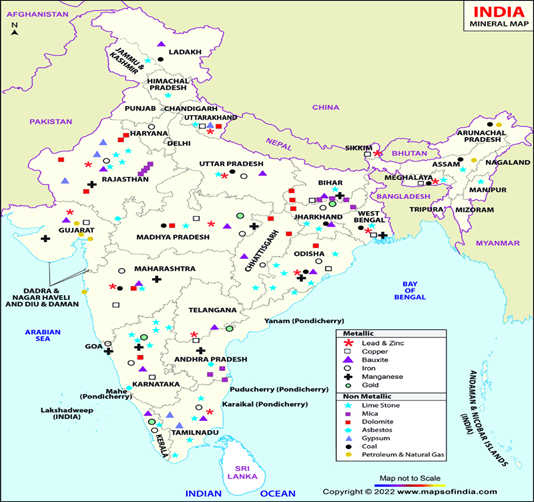

Regional Distribution of Minerals in India

India’s mineral wealth is distributed in specific geographic regions often called mineral belts each characterized by particular geological formations & mineral resources. These regions include plateaus, basins & mountainous terrains which play an essential role in the types of minerals found.

-

North-Western Belt

States Covered: Rajasthan, Haryana, Gujarat

- Key Geological Formations: Aravalli Range, Alluvial deposits

- Mineral Resources:

- Rajasthan: Marble(for construction and sculptures), Limestone (important for cement production), Zinc(used in galvanization), Copper (used in electrical wiring), Gypsum (used in cement and as a fertilizer)

- Haryana: Limestone(for cement manufacturing), Marble (high-quality decorative stone)

- Gujarat: Bauxite(used in the production of aluminum), Salt (for industrial use), Asbestos (used in insulation products)

-

South-Western Belt

States Covered: Maharashtra, Goa, Gujarat

- Key Geological Formations: Deccan Trap, Basaltic lava flows, Sedimentary Basins

- Mineral Resources:

- Maharashtra: Coal(mainly from the Wardha Valley), Manganese (used in steel production), Dolomite(used in steelmaking and as a construction material), Bauxite (important for aluminum production)

- Goa: Iron ore(used in steel production), Manganese (used in steel alloys), Bauxite

- Gujarat: Limestone(used in cement industry), Bauxite, Petroleum (from the Cambay Basin)

-

South-Eastern Belt

States Covered: Andhra Pradesh, Telangana, Tamil Nadu

- Key Geological Formations: Eastern Ghats, Godavari Basin, Kurnool Basin

- Mineral Resources:

- Andhra Pradesh: Bauxite(from Kanduluru and Kuppam), Limestone (important for cement production), Mica (used in electrical and electronics industries)

- Telangana: Coal(from Singareni Collieries), Limestone, Barytes (used in the oil drilling industry)

- Tamil Nadu: Limestone(used in cement), Granite (for construction), Bauxite (important for aluminum industry), Ilmenite (used in titanium production)

-

Eastern Belt

States Covered: Odisha, West Bengal, Jharkhand, Chhattisgarh

- Key Geological Formations: Chhota Nagpur Plateau, Bastar Plateau, Mahanadi Basin

- Mineral Resources:

- Odisha: Iron ore(from Keonjhar and Badampahar), Bauxite, Chromite (used in stainless steel production), Manganese (for steel alloys), Coal (from Talcher)

- West Bengal: Coal(mainly from Raniganj coalfields), Mica, Limestone

- Jharkhand: Coal(from Jharia, the largest coalfield), Iron ore (from Singhbhum), Manganese, Bauxite

- Chhattisgarh: Coal(from Korba), Iron ore, Limestone, Manganese, Bauxite (from Bastar Plateau)

-

Central Belt

States Covered: Madhya Pradesh, Maharashtra, Chhattisgarh

- Key Geological Formations: Vindhyan Range, Mahanadi Basin, Deccan Trap

- Mineral Resources:

- Madhya Pradesh: Coal(from Singrauli), Bauxite (used for aluminum production), Iron ore, Manganese, Diamond (from Panna)

- Maharashtra: Coal(from Wardha Valley), Manganese, Bauxite

- Chhattisgarh: Coal, Iron ore, Limestone, Bauxite

-

Northern Belt

States Covered: Jammu & Kashmir, Himachal Pradesh, Uttarakhand

- Key Geological Formations: Himalayan Range, Shivalik Hills, Lesser Himalayas

- Mineral Resources:

- Jammu & Kashmir: Salt, Mica, Limestone

- Himachal Pradesh: Mica, Gypsum, Limestone, Iron ore

- Uttarakhand: Mica, Magnesite, Limestone

-

North-Eastern Belt

States Covered: Assam, Meghalaya, Nagaland, Arunachal Pradesh, Manipur, Tripura

- Key Geological Formations: Brahmaputra Basin, Shillong Plateau, Tertiary Rocks

- Mineral Resources:

- Assam: Oil(from Dibrugarh, Naharkatia), Natural Gas (from Moran), Coal

- Meghalaya: Coal(from Jaintia Hills), Limestone

- Nagaland: Coal, Limestone, Tin

- Arunachal Pradesh: Coal, Mica, Graphite, Oil(from the Namchik-Namphuk Basin)

- Manipur: Limestone, Coal

- Tripura: Natural Gas, Limestone

-

Southern Belt

States Covered: Karnataka, Kerala, Tamil Nadu

- Key Geological Formations: Deccan Plateau, Nilgiri Hills, Western Ghats

- Mineral Resources:

- Karnataka: Iron ore(from Hospet, Bellary), Manganese, Gold (from Kolar Goldfields), Bauxite

- Kerala: Ilmenite(used in titanium extraction), Monazite (used in thorium extraction), Graphite

- Tamil Nadu: Limestone(important for cement), Granite (for construction), Bauxite, Ilmenite, Thorium(from Monazite sands)

-

Western Coastal Belt

States Covered: Goa, Maharashtra (coastal regions)

- Key Geological Formations: Coastal Sediments, Laterite

- Mineral Resources:

- Goa: Iron ore, Manganese

- Maharashtra (Coastal regions): Limestone, Bauxite

-

Deccan Plateau Belt

States Covered: Karnataka, Telangana, Maharashtra, Andhra Pradesh

- Key Geological Formations: Deccan Trap, Basin Sediments, Granite Ranges

- Mineral Resources:

- Karnataka: Iron ore, Manganese, Gold, Bauxite

- Telangana: Coal(from Singareni Collieries), Barytes, Limestone

- Maharashtra: Coal, Manganese, Bauxite

- Andhra Pradesh: Bauxite, Mica, Limestone

Major Minerals

-

Iron Ore

Types of Iron Ore Found in India:

India has four major types of iron ore classified based on their iron (Fe) content and industrial usability:

| Type |

Iron Content (%) |

Characteristics |

Occurrence in India |

| Hematite |

60-70% |

High-grade, widely used for steelmaking, reddish color |

Odisha, Jharkhand, Chhattisgarh, Karnataka, Goa, Maharashtra |

| Magnetite |

30-60% |

Low-to-medium grade, but can be beneficiated, black color |

Karnataka, Andhra Pradesh, Tamil Nadu, Kerala |

| Limonite |

35-50% |

Hydrated iron oxide, low-grade, yellow-brown color |

Assam, Goa, Karnataka |

| Siderite |

20-40% |

Poor quality due to high silica and phosphorus content |

Bihar, Madhya Pradesh, Rajasthan |

Iron Ore Reserves by State (Percentage Share in Total Reserves wise Ranking):

| State |

Share of Reserves Ranking |

| Odisha |

1 |

| Jharkhand |

2 |

| Chhattisgarh |

3 |

| Karnataka |

4 |

| Goa |

5 |

| Others (Maharashtra, Andhra Pradesh, Tamil Nadu, Kerala) |

6 |

Major Iron Ore Belts:

| Iron Ore Belt |

Major Mines |

States Covered |

Dominant Ore Type |

| Odisha-Jharkhand Belt |

Noamundi, Gua, Joda, Barbil, Kiriburu, Bolani, Thakurani |

Odisha, Jharkhand |

Hematite |

| Durg-Bastar-Chandrapur Belt |

Bailadila, Rajhara, Dalli-Rajhara |

Chhattisgarh, Maharashtra |

Hematite |

| Bellary-Hospet Belt |

Donimalai, Kumaraswamy, Ramandurg |

Karnataka |

Hematite, Magnetite |

| Western Belt (Goa-Maharashtra-Karnataka) |

Codli, Pissurlem, Sonshi |

Goa, Maharashtra, Karnataka |

Hematite |

| Southern Belt (Tamil Nadu-Kerala) |

Kudremukh, Salem |

Tamil Nadu, Kerala |

Magnetite |

Major Iron Ore Mines and Their appx Production:

| Mine Name |

Location (District, State) |

Production Capacity (MT/year) |

Ore Type |

Key Players(Company/Owner) |

| Noamundi |

West Singhbhum, Jharkhand |

10 |

Hematite |

Tata Steel |

| Bailadila |

Dantewada, Chhattisgarh |

40 |

Hematite |

NMDC |

| Kiriburu |

West Singhbhum, Jharkhand |

6 |

Hematite |

SAIL |

| Donimalai |

Bellary, Karnataka |

7 |

Hematite |

NMDC |

| Kudremukh |

Chikkamagaluru, Karnataka |

6 (Defunct) |

Magnetite |

KIOCL |

| Codli |

North Goa, Goa |

7 |

Hematite |

Vedanta |

Major Ports Handling Iron Ore Exports:

| Port Name |

Location (State) |

Annual Iron Ore Handling Capacity (MT) |

Key Export Destinations |

| Paradip Port |

Odisha |

20 |

China, Japan, South Korea |

| Visakhapatnam Port |

Andhra Pradesh |

30 |

China, Japan, Taiwan |

| Mormugao Port |

Goa |

20 |

China, Japan |

| New Mangalore Port |

Karnataka |

15 |

China, South Korea |

| Haldia Port |

West Bengal |

5 |

China, Taiwan |

-

Manganese Ore

Manganese is critical mineral used primarily in steelmaking (90%) where it acts as a deoxidizing and desulfurizing agent. It is also used in battery manufacturing, chemicals, alloys.

Types of Manganese Ore Found in India:

| Type |

Manganese Content (%) |

Characteristics |

Occurrence in India |

| Pyrolusite |

60-63% |

Soft, black, metallic luster, used in batteries and alloys |

Madhya Pradesh, Maharashtra, Karnataka |

| Psilomelane |

45-60% |

Hard, amorphous, contains hydrated oxides |

Odisha, Karnataka, Maharashtra |

| Braunite |

50-55% |

Crystalline, high silica content |

Madhya Pradesh, Gujarat |

| Cryptomelane |

40-50% |

Found in residual and sedimentary deposits |

Jharkhand, Andhra Pradesh |

| Manganite |

35-45% |

Poor-grade ore with high iron and silica content |

Rajasthan, Gujarat |

Pyrolusite and Psilomelane are most valuable manganese ores with high Mn content and industrial usability. India’s manganese ore reserves (~160 million tonnes) contribute ~10% of global resources.

Manganese Ore Reserves by State (Percentage Share in Total Reserves wise Ranking):

| State |

Share of Reserves Ranking |

| Odisha |

1 |

| Karnataka |

2 |

| Madhya Pradesh |

3 |

| Maharashtra |

4 |

| Andhra Pradesh |

5 |

| Others (Jharkhand, Gujarat, Rajasthan) |

6 |

- Odisha is the leading producer with mines in Sundargarh, Kendujhar, Rayagada.

- Karnataka and Madhya Pradesh have major deposits mainly in the Sandur Belt and Balaghat district.

Major Manganese Ore Belts and Mines in India:

Manganese ore is found in Proterozoic sedimentary sequences particularly in the Dharwar Craton and the Eastern Ghats Belt.

| Manganese Ore Belt |

Major Mines |

States Covered |

Dominant Ore Type |

| Odisha Belt |

Barbil, Joda, Gandhamardan, Sundargarh |

Odisha |

Psilomelane, Pyrolusite |

| Balaghat-Bhandara Belt |

Ukwa, Balaghat, Tirodi, Kandri |

Madhya Pradesh, Maharashtra |

Pyrolusite, Braunite |

| Sandur-Hospet Belt |

Sandur, Ramandurg |

Karnataka |

Psilomelane, Pyrolusite |

| Nagpur-Khandhar Belt |

Mansar, Satak, Gumgaon |

Maharashtra |

Braunite, Pyrolusite |

| Visakhapatnam-Srikakulam Belt |

Garividi, Chipurupalle |

Andhra Pradesh |

Cryptomelane, Manganite |

Major Manganese Ore Mines and Their appx Production:

| Mine Name |

Location (District, State) |

Production Capacity (MT/year) |

Ore Type |

Key Players(Company/Owner) |

| Balaghat |

Balaghat, Madhya Pradesh |

5 |

Pyrolusite |

MOIL Ltd. |

| Ukwa |

Balaghat, Madhya Pradesh |

3 |

Pyrolusite |

MOIL Ltd. |

| Tirodi |

Bhandara, Maharashtra |

2 |

Braunite |

MOIL Ltd. |

| Kandri |

Nagpur, Maharashtra |

1.5 |

Pyrolusite |

MOIL Ltd. |

| Sandur |

Bellary, Karnataka |

3 |

Psilomelane |

Private Operators |

| Joda-Barbil |

Kendujhar, Odisha |

6 |

Psilomelane |

Tata Steel, OMC |

- MOIL Ltd. (Manganese Ore India Limited)is India’s largest manganese producer contributing ~50% of total production.

- Odisha’s Joda-Barbil minessupply manganese ore for domestic steel plants.

- Balaghat and Sandur are high-grade manganese mines crucial for India’s ferroalloy and steel industry.

Major Ports Handling Manganese Ore Exports:

| Port Name |

Location (State) |

Annual Manganese Ore Handling Capacity (MT) |

Key Export Destinations |

| Paradip Port |

Odisha |

12 |

China, Japan, South Korea |

| Visakhapatnam Port |

Andhra Pradesh |

8 |

China, Taiwan, Vietnam |

| Mormugao Port |

Goa |

6 |

China, South Korea |

| Mumbai Port |

Maharashtra |

4 |

China, Japan |

| Kolkata Port |

West Bengal |

3 |

China, Taiwan |

-

Bauxite

Bauxite (Al₂O₃·nH₂O) is primary ore for aluminum production. It is also used in refractories, abrasives, cement, chemicals. India has 5th largest bauxite reserves (~3.9 billion tonnes) and contributes ~5% of global production.

Types of Bauxite Found in India:

| Type |

Alumina (Al₂O₃) Content (%) |

Silica (SiO₂) Content (%) |

Characteristics |

Occurrence in India |

| Gibbsite (Trihydrate) |

50-55% |

Low |

Easily refined |

Odisha, Jharkhand, Gujarat |

| Boehmite (Monohydrate) |

45-50% |

Moderate |

Requires high-pressure digestion |

Maharashtra, Tamil Nadu |

| Diaspore (Monohydrate) |

35-45% |

High |

Difficult to process |

Madhya Pradesh, Chhattisgarh |

Gibbsite-rich bauxite is major for aluminum refining. Monohydrate bauxite (Boehmite & Diaspore) requires advanced processing.

Bauxite Reserves by State (Percentage Share in Total Reserves wise Ranking):

| State |

Share of Reserves Ranking |

| Odisha |

1 |

| Andhra Pradesh |

2 |

| Gujarat |

3 |

| Maharashtra |

4 |

| Madhya Pradesh |

5 |

| Chhattisgarh |

6 |

| Tamil Nadu & Others |

7 |

Major Bauxite Ore Belts:

| Bauxite Ore Belt |

Major Mines |

States Covered |

Dominant Ore Type |

| Eastern Ghats Belt |

Panchpatmali, Kodingamali, Gandhamardan |

Odisha, Andhra Pradesh |

Gibbsite |

| Western Belt |

Gadhsisa, Kachchh, Okha, Porbandar |

Gujarat, Maharashtra |

Gibbsite, Boehmite |

| Central India Belt |

Amarkantak, Maikal Hills |

Madhya Pradesh, Chhattisgarh |

Diaspore |

| Southern Belt |

Yercaud, Kolli Hills, Nilgiris |

Tamil Nadu, Kerala |

Boehmite |

Major Bauxite Mines in India:

| Mine Name |

Location (District, State) |

Production Capacity (MT/year) |

Ore Type |

Key Players(Company/Owner) |

| Panchpatmali |

Koraput, Odisha |

6 |

Gibbsite |

NALCO |

| Kodingamali |

Rayagada, Odisha |

3 |

Gibbsite |

OMC |

| Gandhamardan |

Sambalpur, Odisha |

2 |

Gibbsite |

OMC |

| Gadhsisa |

Kachchh, Gujarat |

1.5 |

Boehmite |

GMDC |

| Amarkantak |

Anuppur, Madhya Pradesh |

1 |

Diaspore |

HINDALCO |

| Kolhapur |

Kolhapur, Maharashtra |

1.2 |

Boehmite |

Private Operators |

NALCO operates Panchpatmali mine India’s largest bauxite mine. HINDALCO and NALCO are the major players in India’s bauxite industry.

Major Alumina Refineries in India:

Bauxite is processed in alumina refineries before being converted to aluminum through electrolysis.

| Refinery Name |

Location (State) |

Capacity (MT/year) |

Company |

Bauxite Source |

| Damanjodi Refinery |

Odisha |

2.1 |

NALCO |

Panchpatmali |

| Muri Refinery |

Jharkhand |

0.45 |

HINDALCO |

Jharkhand Mines |

| Belgaum Refinery |

Karnataka |

0.35 |

HINDALCO |

Maharashtra Mines |

| Utkal Alumina |

Odisha |

1.5 |

HINDALCO |

Kodingamali |

| Korba Refinery |

Chhattisgarh |

0.2 |

BALCO |

Madhya Pradesh |

Major Ports Handling Bauxite Exports:

| Port Name |

Location (State) |

Annual Bauxite Handling Capacity (MT) |

Key Export Destinations |

| Paradip Port |

Odisha |

10 |

China, UAE |

| Visakhapatnam Port |

Andhra Pradesh |

6 |

China, Malaysia |

| Kandla Port |

Gujarat |

4 |

China, Middle East |

| Mumbai Port |

Maharashtra |

3 |

Japan, UAE |

| Mormugao Port |

Goa |

2 |

China, Vietnam |

-

Copper

Copper (Cu) is strategic metal used in electrical wiring, electronics, construction, transport, alloys (brass & bronze) & renewable energy technologies. India’s total copper ore reserves are estimated at 1.5 billion tonnes & India contributes ~2% to global copper production.

Types of Copper Ore Found in India:

| Type |

Copper (Cu) Content (%) |

Associated Minerals |

Occurrence in India |

| Chalcopyrite (CuFeS₂) |

25-35% |

Iron, Sulfur, Gold |

Rajasthan, Madhya Pradesh, Jharkhand |

| Bornite (Cu₅FeS₄) |

50-60% |

Sulfur, Iron |

Rajasthan, Andhra Pradesh |

| Chalcocite (Cu₂S) |

60-80% |

Silver, Sulfur |

Madhya Pradesh, Karnataka |

| Malachite (Cu₂(OH)₂CO₃) |

20-30% |

Carbonates |

Jharkhand, Odisha |

Chalcopyrite is the most common copper ore in India.

Copper Reserves by State (Percentage Share in Total Reserves wise Ranking):

| State |

Share of Reserves Ranking |

| Rajasthan |

1 |

| Madhya Pradesh |

2 |

| Jharkhand |

3 |

| Andhra Pradesh |

4 |

Major Copper Ore Belts:

| Copper Ore Belt |

Major Mines |

States Covered |

Dominant Ore Type |

| Aravalli Copper Belt |

Khetri, Kolihan, Banwas |

Rajasthan |

Chalcopyrite, Bornite |

| Singhbhum Copper Belt |

Mosabani, Rakha, Surda |

Jharkhand |

Chalcopyrite, Malachite |

| Malanjkhand Belt |

Malanjkhand |

Madhya Pradesh |

Chalcopyrite, Chalcocite |

| Agni Gundala Belt |

Tummalapalle, Agnigundala |

Andhra Pradesh |

Bornite, Chalcocite |

Major Copper Mines in India:

| Mine Name |

Location (District, State) |

Production Capacity (MT/year) |

Ore Type |

Key Players (Company/Owner) |

| Khetri |

Jhunjhunu, Rajasthan |

1.5 |

Chalcopyrite |

HCL |

| Kolihan |

Jhunjhunu, Rajasthan |

1 |

Chalcopyrite |

HCL |

| Banwas |

Jhunjhunu, Rajasthan |

0.7 |

Bornite |

HCL |

| Malanjkhand |

Balaghat, Madhya Pradesh |

3.5 |

Chalcopyrite, Chalcocite |

HCL |

| Mosabani |

Singhbhum, Jharkhand |

0.6 |

Chalcopyrite |

HCL |

| Surda |

Singhbhum, Jharkhand |

0.3 |

Chalcopyrite |

HCL |

Major Copper Smelters & Refineries in India:

| Refinery Name |

Location (State) |

Capacity (MT/year) |

Company |

Ore Source |

| Khetri Copper Complex |

Rajasthan |

0.3 |

HCL |

Khetri, Kolihan |

| Malanjkhand Refinery |

Madhya Pradesh |

1.2 |

HCL |

Malanjkhand |

| Birla Copper (Dahej) |

Gujarat |

5 |

Hindalco |

Imported Ore |

| Sterlite Copper (Thoothukudi) |

Tamil Nadu |

4.2 |

Vedanta (Closed) |

Imported Ore |

| Jhagadia Copper |

Gujarat |

0.5 |

SWIL |

Imported Ore |

- HCL operates India’s only primary copper smelters using domestic ore.

- Vedanta’s Sterlite Copper in Tamil Nadu was closed in 2018 due to environmental concerns.

- Hindalco’s Dahej refinery is India’s largest processing imported concentrates.

Major Ports:

India imports more refined copper than it exports due to limited domestic ore processing capacity.

| Port Name |

Location (State) |

Annual Copper Handling Capacity (MT) |

Key Trading Partners |

| Mundra Port |

Gujarat |

3 |

Chile, Australia |

| Kandla Port |

Gujarat |

2.5 |

China, Japan |

| Paradip Port |

Odisha |

2 |

China, UAE |

| Visakhapatnam Port |

Andhra Pradesh |

1.5 |

Malaysia, South Korea |

| Mumbai Port |

Maharashtra |

1.2 |

UAE, South Africa |

5. Mica

Mica is a non-metallic mineral known for its heat resistance, insulation properties & flexibility. It is widely used in electrical & electronic industries, paints, cosmetics, construction, aerospace.

Types of Mica Found in India:

| Type of Mica |

Properties |

Major Uses |

Occurrence in India |

| Muscovite (KAl₂(AlSi₃O₁₀)(OH)₂) |

Transparent, dielectric, heat-resistant |

Electrical insulation, cosmetics |

Jharkhand, Andhra Pradesh, Rajasthan |

| Phlogopite (KMg₃(AlSi₃O₁₀)(OH)₂) |

Darker, high-temperature stability |

Foundry, welding electrodes |

Tamil Nadu, Bihar |

| Biotite (K(Mg,Fe)₃(AlSi₃O₁₀)(OH)₂) |

Black, iron-rich, conductive |

Construction, paint industry |

Jharkhand, Karnataka |

Muscovite is most valuable mica type in India. India was historically the largest producer of mica but now contributes ~10% of global production.

Mica Reserves by State (Percentage Share in Total Reserves wise Ranking):

| State |

Share of Reserves Ranking |

| Jharkhand |

1 |

| Andhra Pradesh |

2 |

| Rajasthan |

3 |

| Tamil Nadu & Others |

4 |

Rajasthan produces high-quality muscovite mica.

Major Mica Belts:

| Mica Belt |

Major Mines |

States Covered |

Dominant Mica Type |

| Kodarma-Giridih Belt |

Kodarma, Domchanch |

Jharkhand |

Muscovite |

| Nellore Belt |

Gudur, Brahmanapalli |

Andhra Pradesh |

Muscovite |

| Jaipur-Bhilwara Belt |

Bhilwara, Ajmer |

Rajasthan |

Muscovite |

| Tamil Nadu Belt |

Sivaganga, Madurai |

Tamil Nadu |

Phlogopite |

- The Kodarma-Giridih belt (Jharkhand) is most productive mica region in India.

- Nellore (Andhra Pradesh) produces high-grade sheet mica used in exports.

Major Mica Mines in India:

| Mine Name |

Location (District, State) |

Production Capacity (MT/year) |

Mica Type |

Key Players |

| Kodarma Mine |

Kodarma, Jharkhand |

1,500 |

Muscovite |

Government & Private |

| Domchanch Mine |

Giridih, Jharkhand |

1,200 |

Muscovite |

Private operators |

| Gudur Mine |

Nellore, Andhra Pradesh |

1,800 |

Muscovite |

Private operators |

| Bhilwara Mines |

Bhilwara, Rajasthan |

800 |

Muscovite |

Small-scale units |

| Sivaganga Mine |

Sivaganga, Tamil Nadu |

700 |

Phlogopite |

Government & Private |

- Jharkhand’s Kodarma region was once called the “Mica Capital of the World”.

- Andhra Pradesh’s Nellore district is now the largest producer.

Major Mica Processing Units in India:

India has a strong mica processing industry particularly in Jharkhand, Andhra Pradesh, Rajasthan.

| Processing Unit Name |

Location (State) |

Processing Capacity (MT/year) |

Products |

| Jharkhand Mica Processing Plant |

Kodarma, Jharkhand |

3,000 |

Mica Sheets, Powder |

| Nellore Mica Factory |

Nellore, Andhra Pradesh |

4,000 |

Processed Mica Flakes |

| Rajasthan Mica Industries |

Bhilwara, Rajasthan |

2,500 |

Insulating Mica Parts |

Major Ports Handling Mica Exports:

| Port Name |

Location (State) |

Annual Mica Handling Capacity (MT) |

Key Trading Partners |

| Kolkata Port |

West Bengal |

5,000 |

USA, China, Japan |

| Chennai Port |

Tamil Nadu |

3,500 |

South Korea, Germany |

| Visakhapatnam Port |

Andhra Pradesh |

3,000 |

France, UK |

| Mundra Port |

Gujarat |

2,000 |

European Union |

6. Gold

Gold is a precious metal used in jewelry, investment, electronics & aerospace applications. It is also asset in foreign reserves & is demanded in India’s cultural & economic ecosystem.

Types of Gold Deposits Found in India:

| Type of Gold Deposit |

Characteristics |

Occurrence in India |

| Primary (Lode) Gold |

Found in quartz veins within metamorphic rocks |

Karnataka, Jharkhand, Andhra Pradesh, Tamil Nadu |

| Secondary (Placer) Gold |

Found in alluvial deposits in riverbeds |

Kerala, Maharashtra, Chhattisgarh |

| Refractory Gold |

Gold locked in sulfide ores, requiring special extraction |

Karnataka, Rajasthan, West Bengal |

- Primary gold deposits account for majority of India’s gold reserves.

- Placer gold is extracted on a small scale from river sands.

Gold Reserves by State (Percentage Share in Total Reserves wise Ranking):

| State |

Share of Reserves Ranking |

| Karnataka |

1 |

| Rajasthan |

2 |

| Andhra Pradesh |

3 |

| Jharkhand |

4 |

| Tamil Nadu & Others |

5 |

- Rajasthan and Andhra Pradesh have major untapped gold deposits.

Major Gold Belts:

| Gold Belt |

Major Mines |

States Covered |

Deposit Type |

| Kolar Gold Field Belt |

Kolar, Champion Reef |

Karnataka |

Lode Gold |

| Hutti Gold Belt |

Hutti, Uti, Hirabuddini |

Karnataka |

Lode Gold |

| Ramgiri Gold Belt |

Ramagiri, Bisanatham |

Andhra Pradesh |

Lode Gold |

| Sonapahari Belt |

Parasi, Bhitar Dari |

Jharkhand |

Lode Gold |

| Jonnagiri Gold Belt |

Jonnagiri Mine |

Andhra Pradesh |

Lode Gold |

| Jagpura-Banswara Belt |

Jagpura Mine |

Rajasthan |

Refractory Gold |

- Kolar Gold Fields (Karnataka) were historically India’s largest goldcproducing region but are now closed.

- Hutti Gold Mines (Karnataka) is India’s only active large-scale gold mine.

Major Gold Mines in India:

| Mine Name |

Location (District, State) |

Production Capacity (kg/year) |

Mining Company |

| Hutti Gold Mine |

Raichur, Karnataka |

2,000 |

Hutti Gold Mines Co. Ltd. |

| Uti Gold Mine |

Raichur, Karnataka |

700 |

Hutti Gold Mines Co. Ltd. |

| Hirabuddini Gold Mine |

Raichur, Karnataka |

500 |

Hutti Gold Mines Co. Ltd. |

| Jonnagiri Gold Mine |

Kurnool, Andhra Pradesh |

500 |

Deccan Gold Mines Ltd. |

| Sonapahari Mine |

Ranchi, Jharkhand |

400 |

Private & Government |

| Jagpura Mine |

Banswara, Rajasthan |

300 |

Rajasthan State Mines |

- Hutti Gold Mine is India’s largest & only operational primary gold mine.

- Jonnagiri (Andhra Pradesh) is a developing private-sector gold project.

Gold Refining and Processing Units in India:

India imports major portion of its gold demand necessitating large-scale refining.

| Refinery Name |

Location (State) |

Refining Capacity (tons/year) |

Ownership |

| MMTC-PAMP Gold Refinery |

Haryana |

100 |

Joint Venture |

| Hindustan Gold Refinery |

Maharashtra |

80 |

Private |

| Rajesh Exports Refinery |

Karnataka |

60 |

Private |

| Kolkata Gold Refinery |

West Bengal |

50 |

Government |

| Kundan Gold Refinery |

Delhi |

45 |

Private |

- MMTC-PAMP is India’s largest gold refinery refining both imported & domestic gold.

- Gold refining is concentrated in states with strong industrial hubs like Maharashtra, Karnataka & Haryana.

Major Ports Handling Gold Imports:

| Port Name |

Location (State) |

Annual Gold Handling Capacity (tons) |

Key Trading Partners |

| Mumbai Port |

Maharashtra |

300 |

UAE, Switzerland |

| Chennai Port |

Tamil Nadu |

250 |

South Africa, UK |

| Kolkata Port |

West Bengal |

200 |

Australia, UAE |

| Delhi Air Cargo |

Delhi |

180 |

Singapore, Switzerland |

| Bangalore Air Cargo |

Karnataka |

150 |

South Africa, USA |

7. Silver

Used in jewelry, electronics, solar panels, photography, antimicrobial applications & currency reserves. India does not have large silver reserves & meets its demand through both domestic mining & imports.

Types of Silver Deposits in India:

| Type of Silver Deposit |

Characteristics |

Occurrence in India |

| Primary Silver Deposits |

Found in native form, but rare |

Rajasthan, Karnataka |

| Polymetallic Deposits |

Occurs as a by-product of lead, zinc, and copper mining |

Rajasthan, Andhra Pradesh, Gujarat |

| Epithermal Deposits |

Found in hydrothermal veins with gold and other minerals |

Jharkhand, Karnataka |

| Recycled Silver |

Extracted from scrap, old electronics, and jewelry |

Major urban centers (Delhi, Mumbai, Chennai) |

Major Silver Mines and Fields in India:

| Mine/Region |

State |

Type |

Associated Minerals |

| Zawar Mines |

Rajasthan |

Polymetallic |

Lead, Zinc, Silver |

| Sindesar Khurd Mine |

Rajasthan |

Polymetallic |

Lead, Zinc, Silver |

| Rajpura-Dariba Mine |

Rajasthan |

Polymetallic |

Lead, Zinc, Silver |

| Hutti Gold Fields |

Karnataka |

Epithermal |

Gold, Silver |

| Tummalapalle Mine |

Andhra Pradesh |

Uranium-bearing |

Silver (by-product) |

- Rajasthan accounts for over 90% of India’s silver production mainly from Hindustan Zinc Limited mines.

- Other minor occurrencesare found in Jharkhand, Gujarat, Andhra Pradesh, Karnataka.

Major Silver Processing and Refining Facilities:

| Refinery |

Location |

Company |

Capacity & Features |

| Chanderiya Smelting Complex |

Rajasthan |

Hindustan Zinc Ltd (Vedanta) |

Largest silver producer in India, part of zinc-lead refining |

| Debari Zinc Smelter |

Rajasthan |

Hindustan Zinc Ltd |

Secondary silver production |

| Pantnagar Refinery |

Uttarakhand |

Hindustan Zinc Ltd |

Silver refining from by-products |

| Hutti Gold Refinery |

Karnataka |

Hutti Gold Mines Ltd |

Recovers silver as a gold refining by-product |

Major Ports for Silver Trade and Imports:

| Port |

State |

Role |

| Mumbai Port |

Maharashtra |

Largest silver import hub |

| Chennai Port |

Tamil Nadu |

Handles silver imports from Southeast Asia |

| Kolkata Port |

West Bengal |

Imports silver from Latin America |

| Kandla Port |

Gujarat |

Entry point for silver bullion |

| Nhava Sheva (JNPT) |

Maharashtra |

Largest container port handling silver |

- India imports a significant portion of its silver needs mainly from Mexico, China, Australia, UK.

- Ports like Mumbai, Chennai, Kandlaplay major role in silver importation & distribution.

8. Lead

- Used in batteries (especially for vehicles & backup power), alloys, cable sheathing, radiation shielding, pigments.

- India is a major consumer but a limited producerof lead. A significant portion is imported to meet domestic demand.

Types of Lead Deposits in India:

| Type of Lead Deposit |

Characteristics |

Occurrence in India |

| Primary Lead Deposits |

Found as galena (PbS) in sulfide ores |

Rajasthan, Andhra Pradesh, Tamil Nadu |

| Polymetallic Deposits |

Lead occurs with zinc, silver, and copper |

Rajasthan, Gujarat, Odisha |

| Recycled Lead |

Extracted from used batteries and scrap metal |

Urban centers (Delhi, Mumbai, Chennai) |

Major Lead Mines and Fields in India:

| Mine/Region |

State |

Type |

Associated Minerals |

| Zawar Mines |

Rajasthan |

Polymetallic |

Lead, Zinc, Silver |

| Sindesar Khurd Mine |

Rajasthan |

Polymetallic |

Lead, Zinc, Silver |

| Rajpura-Dariba Mine |

Rajasthan |

Polymetallic |

Lead, Zinc, Silver |

| Rampura-Agucha Mine |

Rajasthan |

Polymetallic |

Lead, Zinc |

| Sargipalli Mine |

Odisha |

Primary |

Lead, Zinc |

| Mokhana Mine |

Gujarat |

Polymetallic |

Lead, Zinc |

- Rajasthan is India’s leading lead producer contributing over 85% of the total production.

- Odisha, Gujarat, Andhra Pradeshhave minor deposits.

Major Lead Processing and Refining Facilities:

| Refinery |

Location |

Company |

Capacity & Features |

| Chanderiya Smelting Complex |

Rajasthan |

Hindustan Zinc Ltd (Vedanta) |

Largest lead smelting facility in India |

| Debari Zinc Smelter |

Rajasthan |

Hindustan Zinc Ltd |

Produces lead as a by-product |

| Pantnagar Refinery |

Uttarakhand |

Hindustan Zinc Ltd |

Processes refined lead |

| Hindustan Lead Refinery |

Tamil Nadu |

Private players |

Secondary lead processing |

| Exide & Amara Raja Recycling Plants |

Various locations |

Exide, Amara Raja |

Major lead recycling units from batteries |

- Recycled leadforms major portion of India’s lead supply mainly from used batteries.

Major Ports for Lead Trade and Imports:

| Port |

State |

Role |

| Mumbai Port |

Maharashtra |

Handles major lead imports |

| Chennai Port |

Tamil Nadu |

Imports lead from Southeast Asia |

| Kolkata Port |

West Bengal |

Key port for lead trade from China & Australia |

| Kandla Port |

Gujarat |

Entry point for lead bullion |

| Nhava Sheva (JNPT) |

Maharashtra |

Major container port for lead processing units |

- India imports lead mainly from China, Australia, Peru, Mexico.

- Ports like Mumbai, Chennai, Kandlafacilitate trade of lead ore and refined lead.

9. Zinc

- Zinc is critical metal used in galvanizing iron and steel, manufacturing alloys, batteries as a rust-resistant coating.

- It also plays major role in production of brass, zinc oxide & is used in automobiles, construction, electrical industries.

- India is among leading producers of zincglobally with major portion of demand being met through domestic production.

Types of Zinc Deposits in India:

| Type of Zinc Deposit |

Characteristics |

Occurrence in India |

| Primary Zinc Deposits |

Found as sphalerite (ZnS) in sulfide ores |

Rajasthan, Gujarat, Andhra Pradesh |

| Polymetallic Deposits |

Zinc occurs with lead, silver, copper, and iron |

Rajasthan, Odisha, Gujarat |

| Secondary Zinc (Recycling) |

Zinc recycled from scrap and old materials |

Urban centers (Delhi, Mumbai, Kolkata) |

Major Zinc Mines and Fields in India:

| Mine/Region |

State |

Type |

Associated Minerals |

| Rampura-Agucha Mine |

Rajasthan |

Polymetallic |

Zinc, Lead, Silver |

| Sindesar Khurd Mine |

Rajasthan |

Polymetallic |

Zinc, Lead, Silver |

| Rajpura-Dariba Mine |

Rajasthan |

Polymetallic |

Zinc, Lead, Silver |

| Zawar Mines |

Rajasthan |

Polymetallic |

Zinc, Lead |

| Rampur-Bhilai Mines |

Andhra Pradesh |

Primary |

Zinc |

| Kayad Mine |

Rajasthan |

Primary |

Zinc |

| Sargipalli Mine |

Odisha |

Primary |

Zinc, Lead |

| Mokhana Mine |

Gujarat |

Polymetallic |

Zinc, Lead |

- Rajasthan is largest producer of zinc contributing around 75-80% of total zinc productionin India.

- Other stateslike Odisha, Gujarat, Andhra Pradesh also major zinc deposits though they contribute relatively less to overall production.

Major Zinc Processing and Refining Facilities:

| Refinery |

Location |

Company |

Capacity & Features |

| Chanderiya Zinc Smelter |

Rajasthan |

Hindustan Zinc Ltd (Vedanta) |

One of the largest zinc refining plants in the world |

| Debari Zinc Smelter |

Rajasthan |

Hindustan Zinc Ltd |

Produces zinc, lead, and silver |

| Pantnagar Zinc Refinery |

Uttarakhand |

Hindustan Zinc Ltd |

Focused on producing high-quality zinc |

| Chittoor Zinc Smelter |

Andhra Pradesh |

Hindustan Zinc Ltd |

Secondary refining plant for zinc |

| Exide & Amara Raja Recycling Plants |

Various locations |

Exide, Amara Raja |

Processes zinc scrap and produces refined zinc |

- Hindustan Zinc Ltd (Vedanta Group)is leading player in India’s zinc refining industry accounting for nearly 90% of total refined zinc production.

- Zinc recyclingis also a growing industry in India mainly focusing on used batteries and industrial scrap.

Major Ports for Zinc Trade and Imports:

| Port |

State |

Role |

| Mumbai Port |

Maharashtra |

Handles major zinc imports |

| Chennai Port |

Tamil Nadu |

Imports zinc concentrates and refined zinc |

| Kolkata Port |

West Bengal |

Key port for zinc imports from Southeast Asia |

| Kandla Port |

Gujarat |

Entry point for zinc concentrate |

| Nhava Sheva (JNPT) |

Maharashtra |

Major port for zinc trade and exports |

- India imports significant quantities of zinc particularly from countries like China, Australia, Peru.

- Ports such as Mumbai, Chennai, Kandlahandle zinc concentrates & refined zinc for both imports and exports.

10. Limestone

- Limestone is sedimentary rock composed primarily of calcium carbonate (CaCO₃) essential for the cement industry, lime production & as building material.

- India is among largest producers of limestone & plays vital role in infrastructure development.

- Applications: Construction (building material), steel industry(fluxing agent), chemical industry (production of lime, calcium carbide) & agriculture (soil conditioner).

Types of Limestone Deposits:

| Type of Limestone |

Characteristics |

Occurrences in India |

| Cement Grade Limestone |

High CaO content, used in cement manufacturing |

Rajasthan, Andhra Pradesh, Gujarat, Madhya Pradesh |

| Chemical Grade Limestone |

High purity, used for industrial purposes |

Rajasthan, Chhattisgarh, Tamil Nadu |

| Flux Grade Limestone |

Low iron content, used in steelmaking |

Karnataka, Odisha, Bihar |

| High-Grade Limestone |

High calcium content, often used in agriculture |

Rajasthan, Tamil Nadu, Madhya Pradesh |

Major Limestone Mines and Fields in India:

| Mine/Region |

State |

Type |

Associated Minerals |

| Guna Limestone Mine |

Madhya Pradesh |

Cement Grade |

Calcium Carbonate, Clay |

| Jaisalmer Limestone |

Rajasthan |

Cement Grade |

Calcium Carbonate |

| Rajpura-Dariba |

Rajasthan |

Chemical Grade |

Calcium Carbonate |

| Malkapur Limestone |

Maharashtra |

Flux Grade |

Calcium Carbonate |

| Kota Limestone Mine |

Rajasthan |

Cement Grade |

Calcium Carbonate |

| Banaskantha Mines |

Gujarat |

Cement Grade |

Calcium Carbonate |

| Limbodara Mines |

Gujarat |

Cement Grade |

Calcium Carbonate |

| Pudupalayam Mine |

Tamil Nadu |

High-Grade |

Calcium Carbonate |

| Sailana Limestone Mine |

Madhya Pradesh |

Cement Grade |

Calcium Carbonate |

- Rajasthancontributes largest share to India’s cement grade limestone production while Madhya Pradesh and Andhra Pradesh are also key producers.

- Odisha, Karnataka, Biharfocus on flux-grade limestone which is critical for steelmaking.

Major Limestone Processing and Refining Facilities:

| Refinery/Plant |

Location |

Capacity & Features |

| UltraTech Cement Plant |

Rajasthan |

Largest cement plant in India, uses limestone extensively |

| Ambuja Cement Plant |

Gujarat |

Key producer of cement-grade limestone |

| Dalmia Cement Factory |

Tamil Nadu |

Significant consumer of limestone |

| Jindal Steel Plant |

Odisha |

Uses limestone as flux in steel production |

- UltraTech Cementand Ambuja Cement are two of largest companies utilizing limestone for cement production.

- Steel plantslike Jindal Steel use limestone as a flux to remove impurities from steel.

Major Ports for Limestone Trade and Imports:

| Port |

State |

Role |

| Kandla Port |

Gujarat |

Handles limestone exports to Asia and Europe |

| Mundra Port |

Gujarat |

Import and export of limestone for cement industry |

| Chennai Port |

Tamil Nadu |

Limestone imports for cement and steel industries |

| Visakhapatnam Port |

Andhra Pradesh |

Handles exports and imports of limestone |

- Ports such as Kandla, Mundra, Chennaiare crucial for trade of limestone especially for cement production and industrial purposes.

11. Dolomite

Dolomite is sedimentary rock primarily composed of calcium magnesium carbonate (CaMg(CO₃)₂). It is used in iron and steel manufacturing as a refractory material in the chemical industry & for agricultural purposes as soil conditioner.

- Dolomite is also used in production of glass& ceramics making it an important industrial mineral.

- India is among largest producers of dolomite contributing significantly to global supplyof dolomite for various industries.

Types of Dolomite Deposits:

| Type of Dolomite |

Characteristics |

Occurrences in India |

| High-Grade Dolomite |

Used for refractory purposes, high MgO content |

Odisha, Madhya Pradesh, Chhattisgarh |

| Chemical Grade Dolomite |

Used in the chemical industry |

Maharashtra, Rajasthan, Gujarat |

| Limestone-Dolomite Mix |

Mixture of limestone and dolomite, used in various industries |

Karnataka, Andhra Pradesh |

Major Dolomite Mines and Fields in India:

| Mine/Region |

State |

Type |

Associated Minerals |

| Durg Dolomite Mines |

Chhattisgarh |

High-Grade |

Magnesium Carbonate |

| Banswara Dolomite Mine |

Rajasthan |

Chemical Grade |

Magnesium Carbonate |

| Kota Dolomite Mines |

Rajasthan |

High-Grade |

Magnesium Carbonate |

| Narsinghpur Dolomite Mines |

Madhya Pradesh |

High-Grade |

Magnesium Carbonate |

| Kalyan Dolomite Mine |

Maharashtra |

Chemical Grade |

Magnesium Carbonate |

| Raigarh Dolomite Mines |

Chhattisgarh |

High-Grade |

Magnesium Carbonate |

- Chhattisgarh, Rajasthan, Madhya Pradeshare major producers of high-grade dolomite suitable for refractory & steel industries.

- Maharashtraand Gujarat produce chemical grade dolomite used in industrial applications.

Major Dolomite Processing and Refining Facilities:

| Refinery/Plant |

Location |

Capacity & Features |

| Jindal Steel Plant |

Odisha |

Uses dolomite as a flux in steel production |

| Rourkela Steel Plant |

Odisha |

Major user of dolomite in steelmaking |

| Tata Steel Plant |

Jharkhand |

Uses dolomite in the production of steel |

- Steel plantslike Jindal Steel, Rourkela, Tata Steel are primary consumers of dolomite as flux in iron and steel production.

Major Ports for Dolomite Trade and Imports:

| Port |

State |

Role |

| Paradip Port |

Odisha |

Handles dolomite exports and imports |

| Mumbai Port |

Maharashtra |

Key port for dolomite exports |

| Chennai Port |

Tamil Nadu |

Handles dolomite trade for industrial purposes |

| Kochi Port |

Kerala |

Dolomite imports and exports for industrial use |

- Ports like Paradip, Mumbai, Chennaihandle dolomite trade especially for use in steel, chemical, refractory industries.

12. Tin

- Tin is soft, silvery-white metalwidely used in soldering, electrical components, packaging (tin cans) & alloy production.

- India has small but significant tin resources contributing to global supply though it is a relatively minor producer compared to other countries.

- Tin is also used in coating steel, chemicals, electronic components.

Tin Deposits and Occurrences in India:

- India’s tin resourcesare primarily located in Jharkhand, Rajasthan, parts of Kerala.

- The producing regionsfocus on tin as by product of mining other minerals like copper and gold.

Major Tin Mines and Fields in India:

| Mine/Region |

State |

Type |

Associated Minerals |

| Rajasthan Tin Mine |

Rajasthan |

Primary Tin Deposit |

Tin (Sn), Mica |

| Hazaribagh Mines |

Jharkhand |

Tin Occurrence |

Tin, Copper, Gold |

| Wayanad Mine |

Kerala |

Tin Occurrence |

Tin, Gold |

| Sundergarh Mine |

Odisha |

Tin as a By-Product |

Tin (Sn), Copper, Iron |

- Jharkhandand Rajasthan are primary regions where tin is either mined directly or occurs as a by-product in other mineral extractions.

Tin Processing and Refining Facilities:

| Refinery/Plant |

Location |

Capacity & Features |

| Hindustan Zinc Ltd. |

Rajasthan |

Processes tin as a by-product of zinc and copper refining |

| Indian Tin Works |

West Bengal |

Refines tin extracted from various Indian sources |

- Hindustan Zincprocesses tin as a by-product during zinc and copper extraction.

- Indian Tin Worksis one of key refineries for tin in India.

Major Ports for Tin Trade and Exports:

| Port |

State |

Role |

| Kochi Port |

Kerala |

Imports and exports tin and its products |

| Mangalore Port |

Karnataka |

Handles tin trade and exports to Southeast Asia |

| Mumbai Port |

Maharashtra |

Major port for tin and tin product trade |

- Kochi, Mangalore, Mumbaiare key ports for import and export of tin in India.

13. Graphite

- Graphite is naturally occurring form of carbon essential in various industrial applicationssuch as lubricants, batteries, electrodes, steel manufacturing, refractories.

- India is one of top graphite producers with significant deposits of high-gradeand medium-grade graphite used for industrial purposes.

- India’s share in global graphite productionis considerable though countries like China dominate global reserves.

Types of Graphite Deposits in India:

- India produces both crystallineand amorphous graphite with crystalline type being more valuable for industrial applications like battery production and electronics.

Major Graphite Mines and Fields in India:

| Mine/Region |

State |

Type |

Associated Minerals |

| Lohari Mine |

Rajasthan |

Crystalline Graphite |

Graphite, Mica |

| Kawal Mines |

Andhra Pradesh |

Crystalline Graphite |

Graphite, Quartz |

| Khundini Mine |

Jharkhand |

Amorphous Graphite |

Graphite, Coal |

| Sundergarh Graphite Mines |

Odisha |

Crystalline Graphite |

Graphite, Quartz |

- Rajasthanand Andhra Pradesh are significant producers of crystalline graphite which is valuable for industrial purposes such as battery production.

- Jharkhandfocuses on amorphous graphite which has applications in lubricants and other industries.

Graphite Processing and Refining Facilities:

| Refinery/Plant |

Location |

Capacity & Features |

| Graphite India Ltd. |

West Bengal |

Leading producer of synthetic graphite for battery and electrode industries |

| National Mineral Development Corporation |

Hyderabad |

Processes graphite for use in various industrial applications |

- Graphite India Ltd. produces synthetic graphite for industrial applications and batteries.

- NMDC also processes natural graphite for diverse industrial uses.

Major Ports for Graphite Trade and Exports:

| Port |

State |

Role |

| Visakhapatnam Port |

Andhra Pradesh |

Handles graphite exports to international markets |

| Kolkata Port |

West Bengal |

Exports natural graphite and its products |

| Chennai Port |

Tamil Nadu |

Exports graphite primarily to East Asia and Europe |

Visakhapatnam and Kolkata are primary ports handling graphite exports in India especially to China and other Asian markets.